Anodes for Metal Extraction

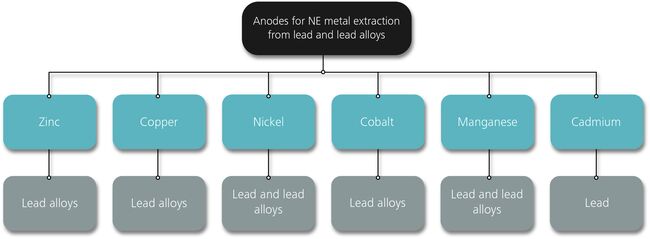

Our rolled anodes for electrolytic metal extraction are suitable for extracting copper, nickel, zinc, cobalt, manganese and cadmium. We provide lead alloys adapted to any metal that can be extracted by electrolysis. We adapt the amounts of the individual alloy elements to meet our customers' specifications, or we advise you in detail using the expertise that we have acquired over many years.

We only manufacture anodes that are made using the rolling process. The advantages are obvious - better density and particle structure. As a result, the tendency to corrode is significantly lower than with cast anodes, and the service life of the anodes is longer. Another positive side-effect is that contamination of the electrolysis baths is lower, and there are fewer impurities in the metal deposited on the cathodes.

Our anodes will impress you with

• their lead alloys, manufactured with great precision

• their high density

• their defined particle structure

• their high resistance to deformation

• their high resistance to corrosion

• the rapid formation of the PbO2 and MnO2 layers

• their low energy consumption

The added value

to you includes a significantly longer service life for the anodes, and therefore greater productivity for your production plant.