Recycling of used anodes - cutting costs

Our "Full-Service-Recycling-Programme" for used anodes from JL production or foreign products can play a part in increasing your value creation chain. It includes the reworking as well as the recycling by us und it ends up in new high-quality lead anodes which provide an excellent result for your electrolysis.

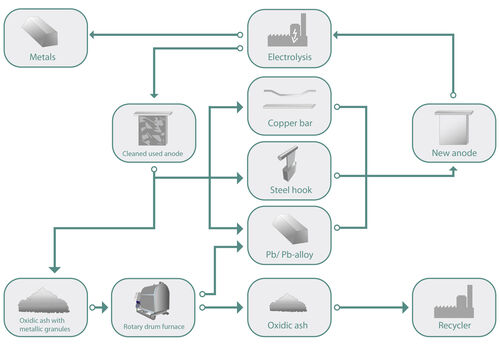

The entire recycling concept is a sustainable way of closing the loop for valuable metals.

At the first stage, we recover the copper support bars from the used anodes supplied to us.

Following internal assessment, re-usable copper support bars and stainless steel hooks undergo cost-effective reprocessing. Copper support bars and stainless steel hooks that are not suitable for re-use are returned to you for disposal, or are fed directly into the recycling loop.

The used anode plates released from the copper support bars are melted down and re-cast as usable metal.

In a second step, the rotary furnace is used to reprocess once again the dross/ash as a valuable recycling product which resulted from the melting process. Thus depending on the type of alloy, a further metal recovery of 40 to 80% from the ash is possible.

The recovered quantity of metal may be supplemented with new metal and adjusted in line with the alloy required.

Ash and dross is weighed and given to the customer, or to reputable reprocessing companies, for the recovery of the metal content.

The entire recycling process is carried out by JL Goslar GmbH in Goslar.

With this "Full-Service-Recycling-Programme", we are able to offer you another component in cost-effective production of new lead anodes for non-ferrous metal extraction.